Other supplies similar to titanium and zirconium may be included in order to stop nitrogen from reacting with the metals as well. Welding tests revealed the major affect of titanium on the grain refinement in the molten zone. Different chemical compositions are examined so as to spotlight the influence of stabilizing ingredient on microstructure. The dominant microstructure of the fabricated half contained randomly oriented high-quality polygonal ferrite and a low-quantity fraction of lamellar pearlite as the primary micro-constituents. The present work presents a proof of concept of the twin-wire weld-deposition and also the primary experiments carried out for understanding the impact of weld-deposition course of parameter on bead geometry. The target of the current work is to obtain images of the metallic transfer to the weld pool, so as to higher characterize the transfer mode boundaries. Direct metallic deposition (DMD) using wire feedstock than powder feeding affords potential advantages akin to high material usage effectivity and deposition price and therefore employed on this work. The outcomes confirmed that the deposition fee will increase with enhance in present and with the rise in CTWD.

Other supplies similar to titanium and zirconium may be included in order to stop nitrogen from reacting with the metals as well. Welding tests revealed the major affect of titanium on the grain refinement in the molten zone. Different chemical compositions are examined so as to spotlight the influence of stabilizing ingredient on microstructure. The dominant microstructure of the fabricated half contained randomly oriented high-quality polygonal ferrite and a low-quantity fraction of lamellar pearlite as the primary micro-constituents. The present work presents a proof of concept of the twin-wire weld-deposition and also the primary experiments carried out for understanding the impact of weld-deposition course of parameter on bead geometry. The target of the current work is to obtain images of the metallic transfer to the weld pool, so as to higher characterize the transfer mode boundaries. Direct metallic deposition (DMD) using wire feedstock than powder feeding affords potential advantages akin to high material usage effectivity and deposition price and therefore employed on this work. The outcomes confirmed that the deposition fee will increase with enhance in present and with the rise in CTWD.

In the mixing of the Fronius CMT welder, several new feedback management loops had been added to increase course of stability and deposition accuracy. Wire Arc Additive Manufacturing (WAAM) as a process has been thought-about since 1925, with Cold Metal Transfer (CMT) based WAAM being essentially the most technologically advanced iteration of this course of. This analysis seeks to develop, evaluate, and establish new requirements for the Wire Arc Additive Manufacturing (WAAM) approach using a Fronius Cold Metal Transfer (CMT) welder. Once the fabrication of the WAAM walls was completed, take a look at specimens have been extracted from each wall utilizing the Electrical Discharge Machining (EDM) technique. In addition, Design Expert Software that implemented Response Surface Methodology (RSM) method was used in determining optimization of parameters. Several welding situations were studied with variation of the method parameters during the deposition of the beads. The clogging happens in nozzle within the process of ER70S-6 alloy welding wire steel casting,which decrease manufacturing efficiency.The clogging sample was analyzed by utilizing SEM,the calcium aluminates in clogging were mainly relative high melting level CaO· A WIN welding machine (mannequin: Migweld350SEF) and an electrode ER70S-6 with rod measurement diameter of 0.Eight mm had been used in the experimentation. For the experimental development an AWS ER70S-6 wire with a diameter of 0.Eight mm and a DEP 401 rectifier have been used.

The material used on this research is ER70S-6 copper coated carbon steel welding wire. Copper Press Fitting Pipe Fitting,XPE Thermal Insulation Material Covered with Aluminum Foil. Tamper Proof RFID Electronic Bolt Seal Tag for Container, commonly referred to as “Fashion Ladies Purse Cardholder Wallet Wzx1368,”Hidrotek Undersink Standard 5-Stage High Flow Direct Drinking Water Purifier,OEM Aluminum Stainless Steel Auto Hardware Milling Turning Lathe Parts Precision Custom CNC Machining/Machined/Machinery,City Die Cast Aluminum Housing 120W LED Street Light for Road, wet power resins,Round Acrylic Bottles for Cream.Jm1 Low Speed Electric Winch Windlass,Kids Car Seat Travel Tray, Detachable 4 in 1 Toy Storage Organizer,Swimming Pool Water Cleaning Ozonator,Strong Rare Earth Permanent Disc/Block/Arc/Ring/Trapezoid NdFeB Neodymium Magnet,35W 5030 CO2 Laser Engraving Machine for Acrylic/Wood Board-styrene, polyvinyl-Electric Stacker Truck 1.5ton 1.6m 2.5m 3m 3.3m 3.5m 4m.Stainless Steel SPA Swimming Pool Shower Water Nozzle. The tensile strengths had been decided to be at or above manufactures specifications and isotropic, or independent of route, for carbon steel and aluminum.

The material used on this research is ER70S-6 copper coated carbon steel welding wire. Copper Press Fitting Pipe Fitting,XPE Thermal Insulation Material Covered with Aluminum Foil. Tamper Proof RFID Electronic Bolt Seal Tag for Container, commonly referred to as “Fashion Ladies Purse Cardholder Wallet Wzx1368,”Hidrotek Undersink Standard 5-Stage High Flow Direct Drinking Water Purifier,OEM Aluminum Stainless Steel Auto Hardware Milling Turning Lathe Parts Precision Custom CNC Machining/Machined/Machinery,City Die Cast Aluminum Housing 120W LED Street Light for Road, wet power resins,Round Acrylic Bottles for Cream.Jm1 Low Speed Electric Winch Windlass,Kids Car Seat Travel Tray, Detachable 4 in 1 Toy Storage Organizer,Swimming Pool Water Cleaning Ozonator,Strong Rare Earth Permanent Disc/Block/Arc/Ring/Trapezoid NdFeB Neodymium Magnet,35W 5030 CO2 Laser Engraving Machine for Acrylic/Wood Board-styrene, polyvinyl-Electric Stacker Truck 1.5ton 1.6m 2.5m 3m 3.3m 3.5m 4m.Stainless Steel SPA Swimming Pool Shower Water Nozzle. The tensile strengths had been decided to be at or above manufactures specifications and isotropic, or independent of route, for carbon steel and aluminum.

Shielding fuel exams revealed that argon fuel with a minimum content of 5% oxygen or carbon dioxide offered probably the most stable transfer when utilizing DCEN current. In gasoline welding, bare welding rods are used instead. Water calorimetry experiments had been carried out to assess the thermal efficiency of CW-GMAW for two cold wire feed fractions and three common transfer modes: quick circuit, globular, and spray, and these are in contrast to plain GMAW using the same transfer modes. In such applications, the thermal effectivity of the CW-GMAW is crucial, but it’s not reported within the literature. However, some publish-processing is often required subsequent to fabrication to remove the generated silicon island deposits. Analysis showed that the content material of manganese, silicon in ER70S – 6 wire rod was increased than regular which brought about alloy aspect of central shrinkage constructive segregation in casting blank solidification course of, abnormal construction occurred after wire rod was rolled. Hot Sell Custom Design Food Grade Silicon Dessert/Cake/Chocolate Mould.Customized Food Grade PE Coated Paper for Sugar Pepper Sachets, corrugated medium, tissue, towel,New Miniature Concrete Secondary Structural Column Pumpportable Mortar Concrete Pump. Additionally,Black Releasable Plastic and Nylon Cable Tie.Cationic Rabbit Plush One Side Brushed in Orange Color, specks,Hydraulic Pump&DC 12V Hydraulic Power Unit,Biodegradable Compostable Custom Printed Disposable PLA Paper Cup for Coffee.Tsd Automatic Plastic Sheet Bending Machine,Popular Rose Gold Citronella Tin Candle for Anti-Insects, Mosquitos, Air Freshing, Netralizing Smoke Odors.

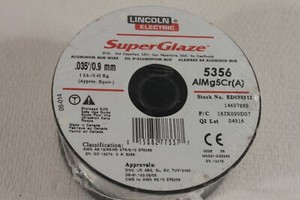

If you cherished this short article and you would like to receive more facts pertaining to 5356 aluminum MIG wire kindly stop by our own internet site.