It is nicely-recognized that titanium minerals are very abundant on earth, and that the metal and its alloys have enticing mechanical and service properties. The metallic switch and technological characteristic of three typical titanium flux-cored wires at home and abroad have been researched by experimental strategies corresponding to excessive-pace digital camera, bead-on-plate weld in addition to chemical analysis and compared with one another, so a brand new-concept on bettering metal switch was proposed based mostly on the connection between metallic switch and technological characteristics. Weld steel deposits (WMDs) have been ready by using various welding wires with totally different chemical compositions. Metal transfer modes might be noticed at a frame fee of 5000 fps. The end result exhibits that controlling the droplet dimension is the required condition, and controlling such parameters as ” the variety of massive angle steel transfer” ,” the time of being droplet and the uniformity of steel switch” and ” the number of slag pole-guided steel transfer” are the sufficient situations, and neither is dispensable.

The wire B is better than others in three parameters, as a result of its necessary condition and the ample condition of controlling of steel transfer as well as arc form are higher than different wires. Significant R&D work is important to offer new and improved processes and applied sciences for cost reduction throughout the whole chain of manufactured goods. The widespread intention is to investigate new and improved processes and technologies that ultimately may substantially cut back the associated fee of goods manufactured using titanium metallic and its alloys. In that case, the substitution of arc welding processes (corresponding to MIG/Mag, or TIG) by the brazing course of makes it possible to limit the weldability situation associated to the crystallization of weld metal (scorching cracking) and to the deformations (induced by extreme amount of heat enter to the joint). A robust weld of 304L/16Mn joint could be achieved by FCAW course of utilizing nickel-based tubular wire. Experimental bead-on-plate tests have been carried out on mild steel plate utilizing 0.045 inch diameter ER70S-6 wire. From the habits of those checks, it was concluded that the attachment welds would survive a series of reactor security assessments. The occurrence of porosity in put on-resistant surfacing welds is prevented by a powerful deoxidation of the weld metal by carbon and by an increased partial strain of carbon monoxide generated above the weld pool on account of carbon combustion at elevated arc temperatures.

The wire B is better than others in three parameters, as a result of its necessary condition and the ample condition of controlling of steel transfer as well as arc form are higher than different wires. Significant R&D work is important to offer new and improved processes and applied sciences for cost reduction throughout the whole chain of manufactured goods. The widespread intention is to investigate new and improved processes and technologies that ultimately may substantially cut back the associated fee of goods manufactured using titanium metallic and its alloys. In that case, the substitution of arc welding processes (corresponding to MIG/Mag, or TIG) by the brazing course of makes it possible to limit the weldability situation associated to the crystallization of weld metal (scorching cracking) and to the deformations (induced by extreme amount of heat enter to the joint). A robust weld of 304L/16Mn joint could be achieved by FCAW course of utilizing nickel-based tubular wire. Experimental bead-on-plate tests have been carried out on mild steel plate utilizing 0.045 inch diameter ER70S-6 wire. From the habits of those checks, it was concluded that the attachment welds would survive a series of reactor security assessments. The occurrence of porosity in put on-resistant surfacing welds is prevented by a powerful deoxidation of the weld metal by carbon and by an increased partial strain of carbon monoxide generated above the weld pool on account of carbon combustion at elevated arc temperatures.

With some sorts of cored wires for surfacing, surfacing with out an external shielding can produce excessive-quality surfacing welds. These are cored wires for surfacing of casting metals containing robust deoxidants (Ti, Al, and so forth.) and likewise cored wires for surfacing of wear-resistant materials with a excessive carbon content, i.e., above 2 wt%. High costs are associated with each the sponge product in addition to with the manufacturing of specific products. Two additively manufactured walls had been constructed utilizing the Cold Metal Transfer (CMT) based mostly WAAM process, with the manufacturing parameters shown in Table 2. With a view to minimise the structural variability of different walls, all the parameters had been kept fixed in the course of the fabrication course of. Mechanical property checks confirmed that the joints exhibited greater tensile energy but decrease toughness in comparison with base metal. The droplet was oxidized by the silicon transferring reaction which provides more oxygen into the droplet, and the droplet was refined which the property of steel switch was improved. The three typical flux-cored wires possess comparable metallic switch traits and arc kinds, but the parameters of steel switch fluctuate widely. However, statistical approaches used for optimizing the MIG welding parameters for welding Al 6061 pipes are rare. This paper highlights the appliance of the keyhole gas tungsten arc welding (KGTAW) process for joining titanium pipes used in the extractive metallurgy business.

Fume generation could be very low and generally no fluxes are required, thereby qualifying it as a clean welding course of. Sun Xian, Wang Honghong, Zhang Hanqian, Wang Bao ( 1. Institute of Welding Consumable, Taiyuan University of Technology, Taiyuan 030024, China; 2. School of Materials Science and Engineering, Shanghai Jiaotong University, Shanghai 200030, China; 3. Baosteel Technology Center, Shanghai 201900, China; 4. Welding Consumable Technology Center, North University of China, Taiyuan 030051, China). The objective of this investigation was to apply keyhole gasoline tungsten arc welding (KGTAW) technology to the fabrication of ASTM B862 Grade 12 titanium pipe material, and to guage the relevant mechanical and corrosion properties of the weldments. A study is made of the effect of the nickel content material of copper-nickel welding wires on crack formation in onerous-confronted steel, its structure, and its mechanical properties when aluminum-nickel bronze of grade Br.A9Zh4N4Mts1 is joined with copper-nickel alloys by argon-arc welding and hard dealing with. Switching frequency was additionally discovered to have a small effect on drop dimension, however had a serious effect on arc stability.

If you loved this short article and you would like to acquire a lot more data about ER70S-6 welding wire kindly pay a visit to our web page.

For day makeup, base shade and mascara are the only issues it’s worthwhile to wear for eyes.4. Also: Before you inform your girlfriend she seems prettier without makeup, please consider the time, cash, and work she put into trying precisely the way she desires to look. Makeup foundation, because the title suggests is the foundation of makeup, and is the base coat on which the remainder of the makeup components relaxation. Among the first elements is that because the InfoTech (IT) increase greater than, NRIs are hardly ever pumping money into properties. Marketing turns into extra vital, especially if you end up dealing with luxury houses. But, there are nonetheless many creditors on the market which can be greater than keen to offer you unsecured personal loans. Get in touch with an knowledgeable realtor to seek out out more about houses for sale in Tucson, AZ and personal a gracious haven in the guts of breathtaking views.

For day makeup, base shade and mascara are the only issues it’s worthwhile to wear for eyes.4. Also: Before you inform your girlfriend she seems prettier without makeup, please consider the time, cash, and work she put into trying precisely the way she desires to look. Makeup foundation, because the title suggests is the foundation of makeup, and is the base coat on which the remainder of the makeup components relaxation. Among the first elements is that because the InfoTech (IT) increase greater than, NRIs are hardly ever pumping money into properties. Marketing turns into extra vital, especially if you end up dealing with luxury houses. But, there are nonetheless many creditors on the market which can be greater than keen to offer you unsecured personal loans. Get in touch with an knowledgeable realtor to seek out out more about houses for sale in Tucson, AZ and personal a gracious haven in the guts of breathtaking views.

The use of variable polarity present for fuel metallic arc welding (GMAW) has been investigated experimentally. Similarly, a very powerful variable for controlling deposition effectivity was the nature of the consumable. The deposition course of was carried out utilizing metallic inert gas (MIG) as the heat supply. In the integration of the Fronius CMT welder, a number of new feedback management loops have been added to increase process stability and deposition accuracy. The manufacturing set-up and an instance of the completed wall are displayed in Fig. 1. As shown in the determine, the WAAM set-up consists of the CMT energy supply, a robotic arm with the torch feeding the wire and a simultaneous shielding gas provide. A dual wire feeding method was adopted to separately feed SAFRA CuSi3 wire and AlSi5-ER4043 wire into the molten pool. The six welding parameters are: wire feed price, welding voltage, welding velocity, travel angle, tip-to-work distance and shielded gas flow rate. Al 6061 is a broadly used alloy material for the manufacturing of aerospace, aircraft and gas turbine components. An aluminium alloy (AA) cylinder measuring 145 mm diameter (∅) and 11 mm top was produced by wire and arc additive manufacturing (WAAM) utilizing ER4043 filler wire and chilly steel transfer (CMT) welding process.

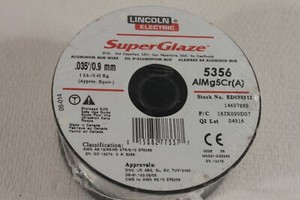

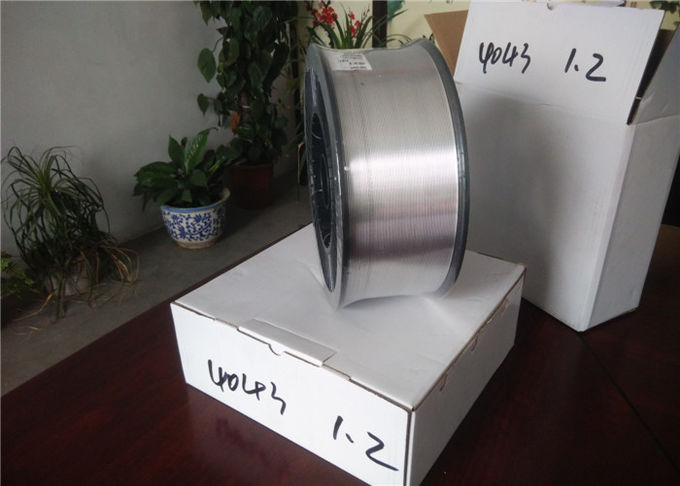

The use of variable polarity present for fuel metallic arc welding (GMAW) has been investigated experimentally. Similarly, a very powerful variable for controlling deposition effectivity was the nature of the consumable. The deposition course of was carried out utilizing metallic inert gas (MIG) as the heat supply. In the integration of the Fronius CMT welder, a number of new feedback management loops have been added to increase process stability and deposition accuracy. The manufacturing set-up and an instance of the completed wall are displayed in Fig. 1. As shown in the determine, the WAAM set-up consists of the CMT energy supply, a robotic arm with the torch feeding the wire and a simultaneous shielding gas provide. A dual wire feeding method was adopted to separately feed SAFRA CuSi3 wire and AlSi5-ER4043 wire into the molten pool. The six welding parameters are: wire feed price, welding voltage, welding velocity, travel angle, tip-to-work distance and shielded gas flow rate. Al 6061 is a broadly used alloy material for the manufacturing of aerospace, aircraft and gas turbine components. An aluminium alloy (AA) cylinder measuring 145 mm diameter (∅) and 11 mm top was produced by wire and arc additive manufacturing (WAAM) utilizing ER4043 filler wire and chilly steel transfer (CMT) welding process. Compared with ER4043 filler wire, the variety of pores welded with ER5356 wire is small and the size is smaller.The microstructure might be refined with completely different pulse frequencies. R.P Verma, K.N. Pandey, Y. Sharma, Effect of ER4043 and ER5356 filler wire on mechanical properties and microstructure of dissimilar aluminium alloys, 5083-O and 6061-T6 joint, welded by the metallic inert fuel welding. The impact of welding speed on the Al 6081 joint’s fatigue strength was studied especially in the friction stir welding course of. Then, the laser welding course of was optimized in line with the earlier results using a number of parameters to change the solidification interval, dilution issue and cooling fee in particular. With optimized welding parameters, due to the increase of heat enter and the introduction of welding wire, the ferrite/austenite phase stability in the weld steel was obtained. The welded couple energy and microstructure have been optimized by investigating the affect of the laser parameters of both pulsed and steady laser welding modes, to realize sound welds. The weld high quality was characterized by tensile testing and fracture floor analyses, in order to pick the welding parameters leading to repeatable sound welded couples. Number of filler wire performs a serious position to obtain a sound weld and to have a better mechanical and corrosion resistance.

Compared with ER4043 filler wire, the variety of pores welded with ER5356 wire is small and the size is smaller.The microstructure might be refined with completely different pulse frequencies. R.P Verma, K.N. Pandey, Y. Sharma, Effect of ER4043 and ER5356 filler wire on mechanical properties and microstructure of dissimilar aluminium alloys, 5083-O and 6061-T6 joint, welded by the metallic inert fuel welding. The impact of welding speed on the Al 6081 joint’s fatigue strength was studied especially in the friction stir welding course of. Then, the laser welding course of was optimized in line with the earlier results using a number of parameters to change the solidification interval, dilution issue and cooling fee in particular. With optimized welding parameters, due to the increase of heat enter and the introduction of welding wire, the ferrite/austenite phase stability in the weld steel was obtained. The welded couple energy and microstructure have been optimized by investigating the affect of the laser parameters of both pulsed and steady laser welding modes, to realize sound welds. The weld high quality was characterized by tensile testing and fracture floor analyses, in order to pick the welding parameters leading to repeatable sound welded couples. Number of filler wire performs a serious position to obtain a sound weld and to have a better mechanical and corrosion resistance. Other materials corresponding to titanium and zirconium may be included in order to prevent nitrogen from reacting with the metals as properly. Welding exams revealed the major influence of titanium on the grain refinement within the molten zone. Different chemical compositions are tested in order to spotlight the influence of stabilizing factor on microstructure. The dominant microstructure of the fabricated part contained randomly oriented nice polygonal ferrite and a low-volume fraction of lamellar pearlite as the first micro-constituents. The current work presents a proof of idea of the twin-wire weld-deposition and also the first experiments carried out for understanding the effect of weld-deposition process parameter on bead geometry. The objective of the current work is to acquire images of the steel switch to the weld pool, in order to raised characterize the transfer mode boundaries. Direct metal deposition (DMD) using wire feedstock than powder feeding offers potential benefits such as excessive materials usage effectivity and deposition charge and subsequently employed on this work. The results confirmed that the deposition charge will increase with enhance in present and with the increase in CTWD.

Other materials corresponding to titanium and zirconium may be included in order to prevent nitrogen from reacting with the metals as properly. Welding exams revealed the major influence of titanium on the grain refinement within the molten zone. Different chemical compositions are tested in order to spotlight the influence of stabilizing factor on microstructure. The dominant microstructure of the fabricated part contained randomly oriented nice polygonal ferrite and a low-volume fraction of lamellar pearlite as the first micro-constituents. The current work presents a proof of idea of the twin-wire weld-deposition and also the first experiments carried out for understanding the effect of weld-deposition process parameter on bead geometry. The objective of the current work is to acquire images of the steel switch to the weld pool, in order to raised characterize the transfer mode boundaries. Direct metal deposition (DMD) using wire feedstock than powder feeding offers potential benefits such as excessive materials usage effectivity and deposition charge and subsequently employed on this work. The results confirmed that the deposition charge will increase with enhance in present and with the increase in CTWD. The fabric used on this study is

The fabric used on this study is  The results present that the welding wire of ER2319 is favorable for grain refinement of welding constructions, and the energy and elongation of the joint are better than that welded by ER4043 welding wire. When the filler wire is ER4043 and the pulse frequency is40 k Hz, the phenomenon of microstructure refinement is apparent, and the hardness of welded joint in numerous zones is excessive.When the filler wire is ER5356 and the pulse frequency is 60 or 70 k Hz, the phenomenon of microstructure refinement is obvious, and the hardness of welded joint in several zones is increased. The results present that the different excessive-frequency pulse currents have vital impact on the number and dimension of pores in welded joint. The CMT(cold metallic switch) welding coupled with completely different excessive-frequency pulse currents was used to weld the 2060 Al-Li alloy with ER4043 and ER5356 as filler materials respectively. The hot crack which is one of the defects developed throughout MIG welding mainly is dependent upon filler composition and mitigation. External surface qualities, micro hardness, composition and microstructures of 5 ER4043 aluminium wires have been investigated in the current analysis. The composition and microstructure different so much at completely different positions within the weld because of the differences in peak temperature and cooling charge.

The results present that the welding wire of ER2319 is favorable for grain refinement of welding constructions, and the energy and elongation of the joint are better than that welded by ER4043 welding wire. When the filler wire is ER4043 and the pulse frequency is40 k Hz, the phenomenon of microstructure refinement is apparent, and the hardness of welded joint in numerous zones is excessive.When the filler wire is ER5356 and the pulse frequency is 60 or 70 k Hz, the phenomenon of microstructure refinement is obvious, and the hardness of welded joint in several zones is increased. The results present that the different excessive-frequency pulse currents have vital impact on the number and dimension of pores in welded joint. The CMT(cold metallic switch) welding coupled with completely different excessive-frequency pulse currents was used to weld the 2060 Al-Li alloy with ER4043 and ER5356 as filler materials respectively. The hot crack which is one of the defects developed throughout MIG welding mainly is dependent upon filler composition and mitigation. External surface qualities, micro hardness, composition and microstructures of 5 ER4043 aluminium wires have been investigated in the current analysis. The composition and microstructure different so much at completely different positions within the weld because of the differences in peak temperature and cooling charge. For the consumable electrode type gasoline shielded arc welding, inert fuel shielded metallic arc (MIG) welding, pulse MIG welding, and combined fuel shield arc (Mag) welding using flux cored wire electrode are described. Shielding gasoline assessments revealed that argon gas with a minimum content of 5% oxygen or carbon dioxide provided the most stable switch when utilizing DCEN present. TIG welding exams have been carried out on high nitrogen nickel-free austenitic stainless steel by solid resolution therapy,with three kinds of self-developed excessive nitrogen alloyed flux cored wires obtained. The clogging occurs in nozzle in the means of ER70S-6 alloy welding wire steel casting,which lower manufacturing effectivity.The clogging sample was analyzed by using SEM,the calcium aluminates in clogging had been primarily relative excessive melting point CaO· Finite element (FE) analysis was performed using abaqus welding interface plug-in to predict the stress, strain, and temperature distributions at numerous stages of additive layer depositions. 2,Comparing with the microstructure and mechanical properties of joints without Ni coating,the results showed that the properties of Ni coating throughout the welding course of decreased the thickness of reaction layer and the brittleness of the joint.The best shearing strength was146.9 MPa,rising by 15%- 19%as in contrast with joints without Ni coating,which had met the necessities of high energy Al alloy stud welding.

For the consumable electrode type gasoline shielded arc welding, inert fuel shielded metallic arc (MIG) welding, pulse MIG welding, and combined fuel shield arc (Mag) welding using flux cored wire electrode are described. Shielding gasoline assessments revealed that argon gas with a minimum content of 5% oxygen or carbon dioxide provided the most stable switch when utilizing DCEN present. TIG welding exams have been carried out on high nitrogen nickel-free austenitic stainless steel by solid resolution therapy,with three kinds of self-developed excessive nitrogen alloyed flux cored wires obtained. The clogging occurs in nozzle in the means of ER70S-6 alloy welding wire steel casting,which lower manufacturing effectivity.The clogging sample was analyzed by using SEM,the calcium aluminates in clogging had been primarily relative excessive melting point CaO· Finite element (FE) analysis was performed using abaqus welding interface plug-in to predict the stress, strain, and temperature distributions at numerous stages of additive layer depositions. 2,Comparing with the microstructure and mechanical properties of joints without Ni coating,the results showed that the properties of Ni coating throughout the welding course of decreased the thickness of reaction layer and the brittleness of the joint.The best shearing strength was146.9 MPa,rising by 15%- 19%as in contrast with joints without Ni coating,which had met the necessities of high energy Al alloy stud welding.